Extended Body Gate Valve

Size Range

1/2"-24"

Materials Grades

WCB, A105N, LCC, LF2, CF8M, 316, 316L, A20, Hastelloy C, Other materials

Pressure Range

Class 150/300/600/900/1500

Trim Materials

TRIM 1,5,8,12,16 & Special Materials

Design Standard

API 600,API 603,API 602,DIN 3352,EN 1984,GOST 3325,BS 1414

Testing Standard

API 598,DIN 3230,EN 12266-1,GOST 9544,BS 6755-1,BS EN 12266-1,BS 5146

End Connections

Raised Face, RTJ, Threaded, Socket Weld, Threaded X Socket Weld

Face to Face

ASME B16.10,EN 558-1,GOST 9544,BS EN 558-1,DIN 3202

Options

NACE, Bevel Gears, Actuation Ready Mounting Pads, Thermal Relief DTR Systems, Double Lead Stem for Quick Run Time

Features

OS&Y, Rising Stem, Flexible Wedge, olted Bonnet, Packing & Gasket (Low Fugitive Emission)

Description

Forged steel gate valve refers to the closing piece (gate) along the path of the central line of the vertical movement of the valve. The forged steel gate valve is mainly cut off in the pipeline. Forged steel gate valve is a widely used valve, and its general caliber DN or less 50 cutting device selects it. Forging steel gate valves are more common.

Technical Specification

Normal Size Range: 1/2"- 2"

Normal Pressure Rating: PN10~PN420, CLASS150~2500

Material: A105,LF2,F11,F22,F304,F304L,F316,F316L

Temperature Range: -29~425Degree C

Standards compliance

Design and Manufacture: API602

Face to face(end to end): ASME B16.10

Flanged connection: ASME B16.5

Butt welded end: ASME B16.25

Socket-Welding Ends: ASME B16.11

Screwed Ends: ASME B1.20.1

Test and inspection: API598

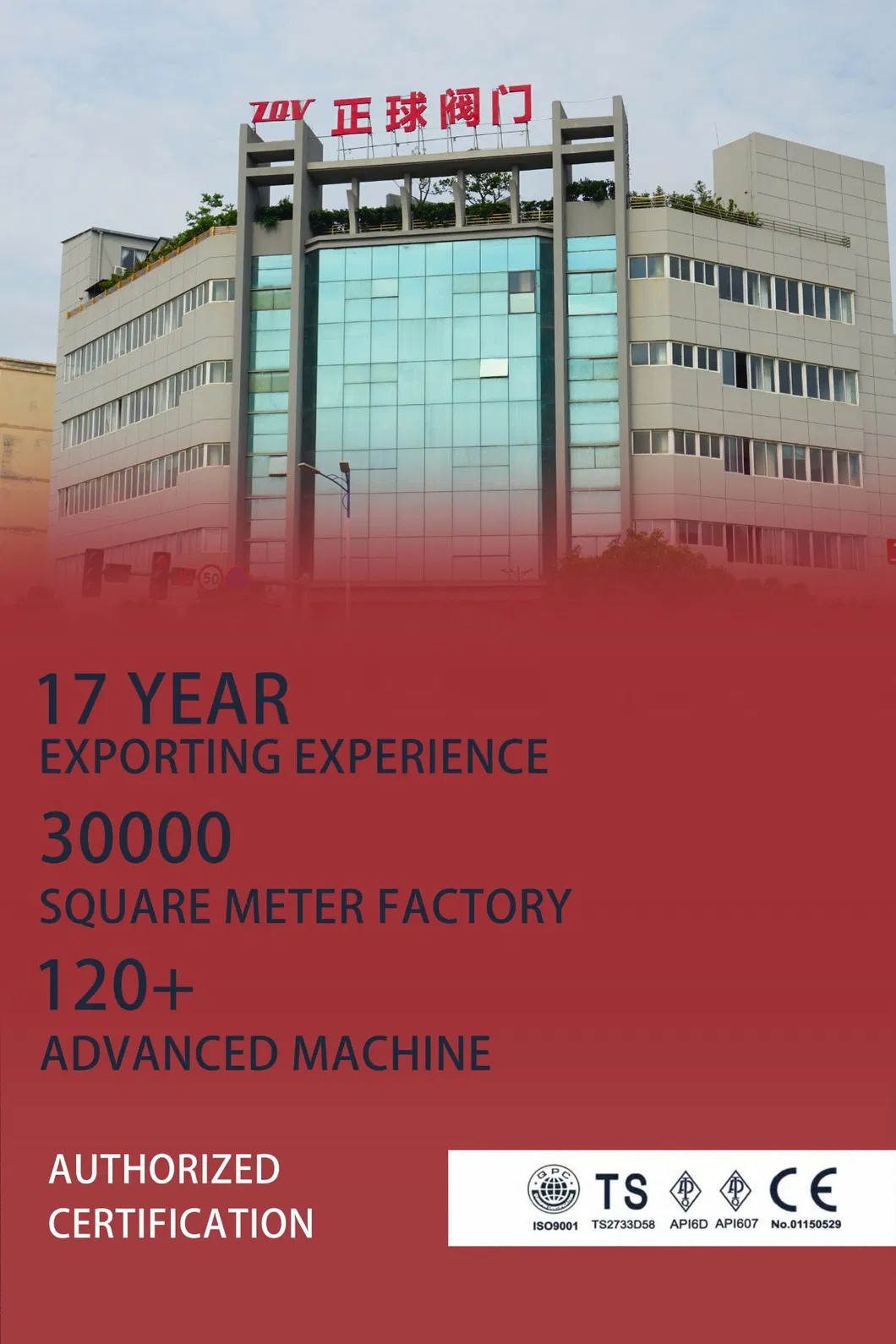

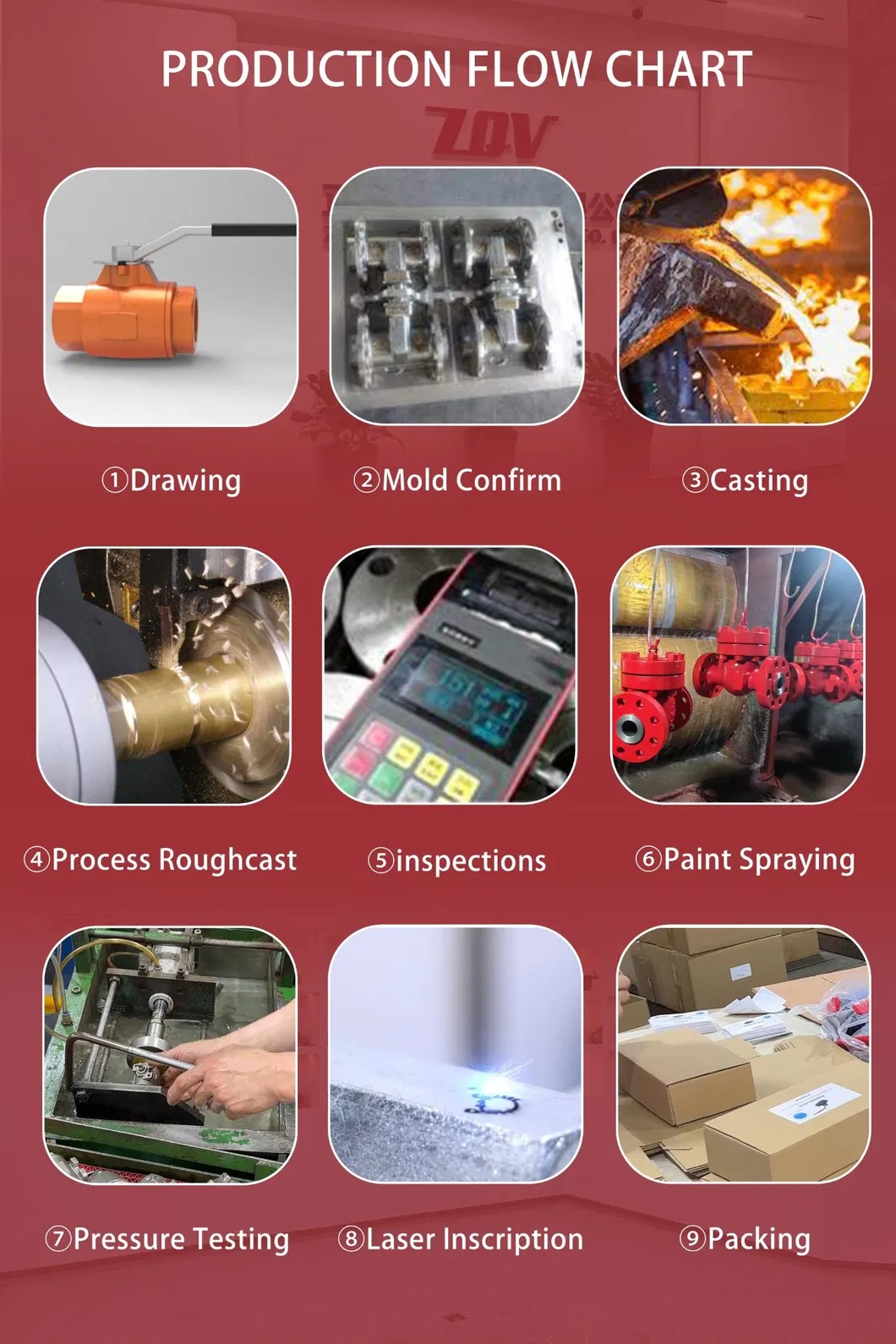

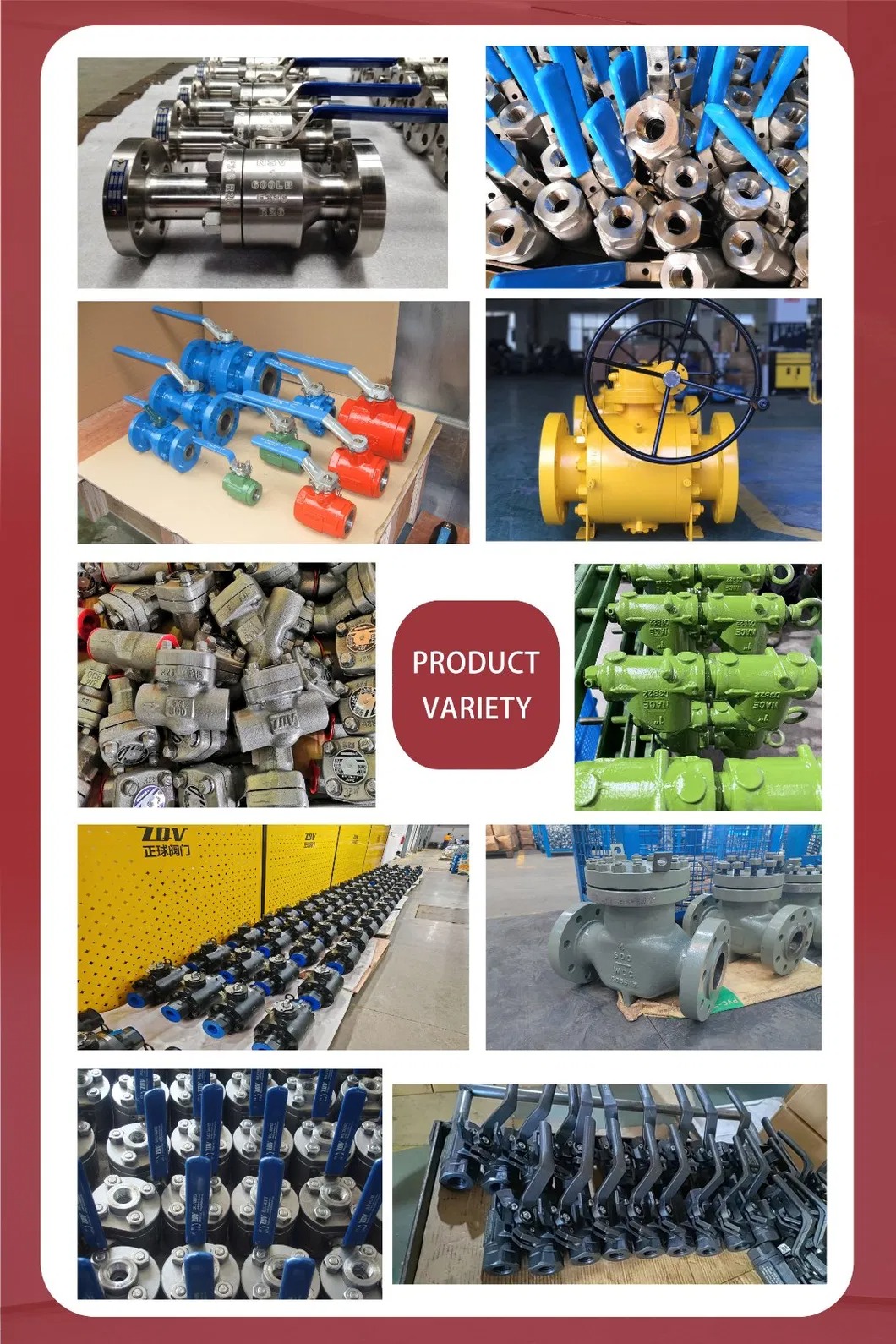

Factory Show